RIO TINTO: Assessment of integrity in 33 overhead cranes

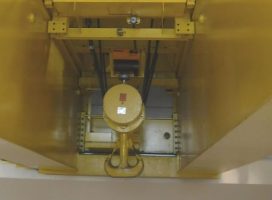

AXS INGENIERIE collaborates with RIO TINTO in a mission to assess the integrity of 33 overhead cranes in RIO TINTO’S Aluminum foundry in Dunkirk.

The assessment of integrity of 33 cranes:

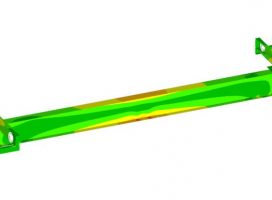

The 33 cranes manufactured by REEL, DEMAG, and ECL, will be the subject of an assessment in order to determine their state of fatigue. The assessment consists of a complete reconstruction of the crane’s history using the VIGILEV© method, and determining its fatigue and ageing factors, in order to analyze the crane’s remaining duty lifetime.

An inspection program is then established for the customer based on risk factors and the previously mentioned data.

RIO TINTO

Founded in 1991 in the north of France, more precisely in Dunkirk, RIO TINTO’S factory specializes in aluminum production. With a production capacity of 270 000 metric tons per year, the factory is the first producer of aluminum in France.

The importance of the VIGILEV© method:

The method that was created by AXS INGENIRIE is used to achieve an assessment in compliance with the French CETMEF recommendations, and the ISO 12482 standard. In addition, this method takes into account the data from operations to complete the risk analysis that was previously done. In 2018, AXS INGENIERIE deployed this method of structural fatigue assessment on more than 65 machines of handling and heavy duty (Cranes, STS cranes, Overhead cranes, RoRo bridges)

Photo Credit : Rio Tinto